The Sindh is a historical region situated in the Indus Valley, it is today one of the four provinces of Pakistan. This region is famous for its production of glazed ceramic (see Kashi gari).

Author: katia

Rajola

Porcelain

Porcelain is a hard, white, non-porous and translucent variety of ceramic ware invented in China around 800 AD. The clay is made of feldspath, quartz, petuntse (china-stone), and kaolin (china-clay). Petuntse (pai-tun-tzu) means hard paste in Chinese. Kaolin is said to be a corruption of the Chinese Kau-ling, meaning High Ridge, the name of a hill east of King-te-chen. This city is in the eastern province of Kiang-si, whence the earliest samples of the clay were sent to Europe in the early 18th century by the Père d’Entrecolles, a French Jesuit missionary.

Chinese porcelain was immensely prized throughout the Orient and Europe. The secrets of its ingredients and production process were closely guarded for nearly a thousand years. It was indeed only in the early 18th century that, by sheer accident, Johann Schnoor, a Prussian, noticed an intensely white material sticking to his horses’ hooves. Curiously, he found it to be an excellent material for whitening wigs. A chemist analyzed the material and identified it as kaolin, one of the main ingredients of porcelain. As a result, the first European production centre of porcelain was started in 1710 in Prussia, in the city of Meissen.

The discovery of kaolin at Saint-Yrieix, near Limoges, in France, and in Cornwall about the year 1750, enabled the extension of porcelain production throughout Europe. The main manufactures were: Vienna, Berlin, Venice, Chelsea and Worcester in England, Tournai in Belgium, Copenhagen, Saint-Petersburg, and Chantilly, Mennecy, Vincennes, and Sceaux, in France.

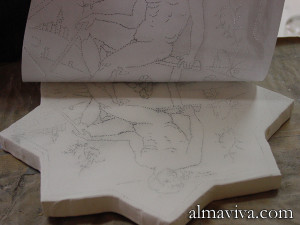

Stencil

A stencil is a perforated paper used to reproduce a decoration.

The stencil is laid on the unbaked glaze and covered with charcoal powder. The black powder goes through the perforated holes and leaves dots on the white glaze. Those dots give an outline and help the painters. Stencils are also used to paint frescoes. The French word for stencil pochoir is also used in English.

Pombalino

Pombalino azulejos are Portuguese glazed tiles with geometric patterns of various colours.

The pombalino azulejos were produced in vast quantities when Lisbon was rebuilt after the devastating 1755 earthquake. The Marquis of Pombal (1699-1782) was Prime Minister of Portugal under King Joseph 1st and gave his name to this type of azulejos.

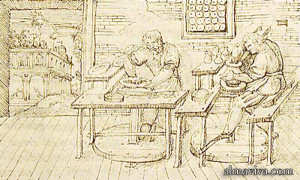

Piccolpasso

Cipriano Piccolpasso (1524-1579) was a renowned Italian potter during the Renaissance.

Piccolpasso was born in Castel Durante, a city in the duchy of Urbino, in Umbria, that was an important centre for the manufacture of maiolica. He published in 1557 the first comprehensive treatise on maiolica techniques: Li Tre Libre Dell’ Arte Del Vasaio (The 3 Books of the Potter’s Art). The treatise was written at the request of the French ambassador to Rome, cardinal François de Tournon, who was motivated by the improvement of French faience manufacturing. The manuscript is enriched with many drawings of Piccolpasso that explain in lively detail the basic procedures for maiolica production. The book includes a selection of designs for plate decoration. The manuscript is now conserved in London in the collections of the Victoria and Albert Museum.

Overglaze

The expression overglaze is used when the decoration is painted on the already-fired glaze, and then fired again at lower temperature. Overglaze colours are thus superficial and therefore more fragile and susceptible to abrasion than under-glaze colours. This technique is known as petit feu in French.

Palissy

Bernard Palissy (1510-1590) was a dedicated French potter, chemist, and enameler during the Renaissance.

He is renowned for his struggle to create new techniques of enameled ceramic ware known as “faïence” in France. According to his own writings, he was at times so poor that he had to use his furniture and floor boards as kiln fuel. He developed his own style of pottery, covered with life-sized replicas of amphibians, reptiles, insects, and plants. This type of ware, known as rustiques figulines (“rusticware”), became so admired that in 1563 he was named King’s Inventor of Rustic Ceramics, and in 1567 he was summoned by Catherine de Medici to decorate her palace of the Tuileries. Palissy rejected the idea that the biblical flood could have deposited fossils throughout the world, even on the highest mountaintops. For opposing such theological belief, and for being an alchemist and Hugenot, he was arrested and eventually died in the Bastille.

Oxides

Natural metal oxides are used in glazing as colour pigments. The colours are revealed only once the glaze is fired in the kiln.

The 5 main oxides are:

– iron: brown and ochre

– copper: dark green

– cobalt: blue (the most used colour in azulejos and Delftware)

– manganese: aubergine colour (often combined with blue)

– antimony: yellow.

Under-glaze

An under-glaze decoration is hand-painted upon the raw and unbaked glaze.

Colour pigments (see Oxides) are gently laid upon the unbaked glaze and then fired in the kiln together with the glaze. The firing lasts about 12 hours at a high temperature of about 1,000° C (or 1,820° F). Colours then merge with the glaze and are thus very resistant to abrasion. This technique is called grand feu in French (″high fire”).